In the dynamic landscape of cosmetics manufacturing, the choice of packaging machinery plays a pivotal role in determining product quality, shelf life, and overall appeal. One such critical component is the transparent film packaging machine. These machines have gained prominence for their versatility, efficiency, and ability to maintain product integrity throughout the supply chain. This article delves into the various applications of transparent film packaging machines within the cosmetics market, exploring how they contribute to the industry’s evolving standards.

1. Customizable Packaging Solutions

Transparent film packaging machines offer a high degree of customization. They can be tailored to meet the specific needs of cosmetic products, from small sample-sized containers to large retail units. This flexibility is crucial for manufacturers looking to cater to diverse markets, including niche products or those targeting eco-conscious consumers who prefer lightweight and easily recyclable packaging options.

2. Enhanced Product Presentation

One of the key advantages of using transparent film packaging is its ability to showcase the product inside. In the cosmetics sector, where appearance and branding are paramount, this transparency allows for direct visual engagement with the consumer. It enables potential customers to see the texture, color, and overall aesthetics of the product, enhancing the purchase decision process. This is particularly beneficial for luxury cosmetics brands seeking to highlight their products’ premium nature through presentation.

3. Preservation of Quality and Freshness

Transparent film packaging not only protects cosmetics from external contaminants but also helps maintain the product’s quality and freshness. By minimizing exposure to light, air, and humidity, these machines prevent degradation that can lead to discoloration, spoilage, or loss of efficacy. This is especially important for products containing sensitive ingredients such as oils, fragrances, and vitamins, which can be adversely affected by prolonged exposure to environmental factors.

4. Increased Efficiency in Manufacturing Processes

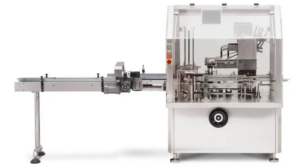

The integration of transparent film packaging machines in the cosmetics manufacturing process significantly boosts productivity. These machines can operate at high speeds, reducing the time needed for packaging, and thus increasing throughput. They automate the process of sealing, labeling, and stacking products, reducing the need for manual labor, which minimizes errors and saves on labor costs. Moreover, automation reduces the risk of contamination, ensuring that each product is handled hygienically, which is essential in a hygiene-sensitive industry like cosmetics.

5. Compliance with Regulatory Standards

In the cosmetics industry, compliance with strict health and safety regulations is non-negotiable. Transparent film packaging machines often come equipped with features that ensure adherence to international packaging standards. These include precise measurement and weighing capabilities, which are crucial for maintaining product quality and meeting regulatory requirements regarding ingredient content and packaging specifications.

6. Sustainable Packaging Options

Recognizing the growing importance of sustainability, many cosmetic companies are adopting transparent film packaging as part of their green initiatives. These materials are often recyclable and require less energy to produce compared to other packaging types. By choosing transparent film packaging, companies can reduce their environmental footprint while appealing to consumers who value eco-friendly practices.

Conclusion

The application of transparent film packaging machines in the cosmetics market is multifaceted, offering benefits that range from enhanced product presentation and quality preservation to increased operational efficiency and sustainable practices. As the cosmetics industry continues to evolve, the integration of advanced packaging technologies like these will likely become even more integral, shaping the future of cosmetic product packaging and contributing to improved consumer experiences and environmental stewardship.

pinfupacking

pinfupacking

HelloPlease log in