Pioneering the Packaging Industry with High-Efficiency Smart Dual-Frequency Inverter Control Packaging Machine

In the rapidly evolving landscape of modern manufacturing, packaging machinery serves as a critical link in the production chain, directly influencing a company’s operational efficiency and market competitiveness. An outstanding packaging equipment not only boasts high productivity but also embodies smart control, user-friendly interfaces, and precision execution capabilities. This article will delve into an innovative packaging machine equipped with dual-frequency inverter control technology, highlighting its unique features and advantages that have ushered in a new era for the packaging industry.

High Efficiency and Energy Saving with Precise Control

At the heart of this machine is its dual-frequency inverter control design. This feature enables rapid adjustments to packaging speeds while maintaining extremely high accuracy during low-speed operations, ensuring consistency in the quality of each packaged item. Compared to traditional packaging equipment, it significantly boosts production efficiency, while also reducing energy consumption, achieving a harmonious balance between economy and environmental sustainability.

User-Centric Interface, Easy Parameter Setting

One of the standout characteristics of this device is its human-centric design. The intuitive touch panel allows users to effortlessly configure a variety of parameters, including packaging length, cutting positions, among others. A simple and streamlined interface, combined with intelligent functionality, significantly reduces the learning curve, making the device accessible even to non-experts, thus enhancing overall operational efficiency.

Fault Self-Diagnosis, Convenient Maintenance

An integrated fault self-diagnosis system serves as a vital safety and convenience feature. Should the machine encounter any anomalies, the system automatically identifies and displays the fault information, enabling maintenance personnel to quickly pinpoint the issue, thereby reducing downtime and ensuring the continuity and stability of the production line.

Precise Tracking and Accurate Positioning

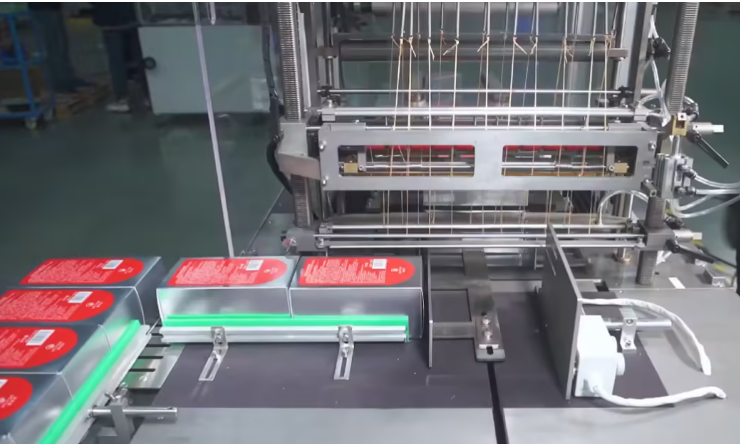

The machine employs highly sensitive photoelectric eyes for color label tracking, complemented by digital input for sealing and cutting positions, ensuring a higher degree of accuracy in packaging. Whether dealing with intricate patterns on labels or the precise packaging of products, the machine executes tasks with precision, guaranteeing the perfection of each product’s packaging.

Temperature Independent PID Control, Versatile Material Handling

The temperature-independent PID (Proportional Integral Derivative) control system is another key highlight in the process control of this device. Through meticulous temperature regulation, it accommodates the packaging needs of a wide range of materials, from thermosensitive ones to those with strong thermal resistance, enhancing the versatility and applicability of the equipment.

Positioning Stop and Smart Protection

Smart features include a positioning stop function that prevents overcutting or tool adhesion, minimizing material wastage and further optimizing the packaging process. The simple yet robust drive system ensures stable operation, facilitating easier maintenance, extending the lifespan of the equipment, and promoting reliability.

Software-driven, Flexible Upgrades

The software-based control is a trend in modern packaging machinery. All control logic of this device is implemented through software, providing the convenience for operators to adjust functions according to their actual needs and laying the foundation for future technological upgrades, ensuring the device remains technologically advanced and competitive in the market.

In conclusion, this dual-frequency inverter control smart packaging machine, with its high-efficiency packaging capability, user-friendly human-machine interaction, precise execution control, reliable maintenance convenience, and forward-thinking technology layout, has led the way in the wave of industrial automation. Whether in the day-to-day operations of the production line or in the planning for the future, it has become an indispensable tool for boosting a company’s competitiveness. With ongoing advancements in technology, we look forward to more such innovative achievements driving the global manufacturing sector towards greater智能化 transformation.

pinfupacking

pinfupacking

HelloPlease log in