The mosquito repellent liquid filling and cartoning labeling

The mosquito repellent liquid packaging line involves an integrated process that combines manual and automated steps to package three bottles and one applicator into boxes. This advanced system ensures quality control and productivity through its well-designed workflow.

Initiating with a precise manual step, experienced operators insert three insect repellent bottles and one applicator into plastic carriers, concurrently acting as a quality check and counting mechanism for subsequent automation.

Central to the operation is the belt conveyor, featuring a flexible and adaptable design to handle various product volumes. It efficiently transfers the filled trays, enhancing throughput without sacrificing accuracy.

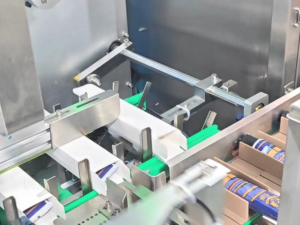

A key highlight is the automatic packaging mechanism, utilizing dual-sided belt grippers to neatly upright the packaged items, facilitating efficient box assembly. This technology reduces manual labor while ensuring consistent box formation.

Safety is given due importance, with safety features like circuit breakers and leakage detection incorporated. Emergency stop buttons are strategically positioned near each workstation to swiftly halt operations in case of emergencies.

All equipment components are sourced from reputable suppliers for reliability and durability. The overall design follows GMP standards (Good Manufacturing Practices), ensuring adherence to cleanliness, hygiene, and industry regulations.

In summary, this mosquito repellent liquid packaging line is a blend of efficiency and precision, catering to modern manufacturing requirements. It minimizes errors, boosts productivity, and showcases a modular setup that adheres to international best practices in packaging processes.

复制内容导出Word

pinfupacking

pinfupacking

HelloPlease log in