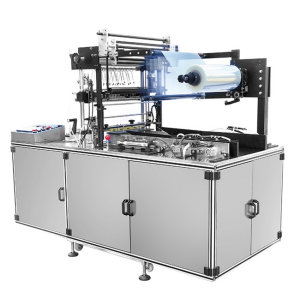

Transparent film three-dimensional packaging machines, often referred to as 3D transparent film packers, vacuum packing machines, or even cigarette wrappers, are specialized machinery designed for the precise and efficient packaging of goods. Utilizing BOPP (Biaxially Oriented Polypropylene) film or PVC (Polyvinyl Chloride), these machines transform various products into compact, cubic, and sealed packages through an automated process.

Industry Applications

Ranging from cosmetics, pharmaceuticals, food, health care products, audio-video materials, stationery, daily-use items, to countless other industries, these packaging systems emulate the distinctive appearance of cigarette packaging, offering an array of functional and aesthetic advantages.

Key Features and Capabilities

A transparent film three-dimensional packaging machine encompasses a multitude of functionalities, including automatic feeding, wrapping, folding, side sealing, end sealing, bottom and top shaping, counting, among others. A notable feature is its capability to automatically apply tamper-evident pull-tabs. These pull-tabs can be customized with diverse colors and company logos, thereby enhancing their anti-counterfeiting function.

Eco-Friendly and Cost-Effective

The use of these machines is characterized by their environmental friendliness and energy conservation. They significantly reduce packaging material costs, while also ensuring neat and visually appealing packages. Full enclosure in packaging not only mitigates dust, moisture, and contamination, but also provides robust protection against counterfeits, making them a valuable addition to any production line.

Focus on Quality and Safety

For the tobacco industry, where the focus is on product quality and safety, specialized transparent film three-dimensional packaging machines, or ‘smoke-packers’, play a pivotal role. These machines are meticulously designed to prioritize packaging integrity and counterfeiting prevention, ensuring that each packaged item is secure and authentic.

Commonality and Specialization

While there is an overlap between the functions and applications of transparent film three-dimensional packaging machines and those utilized specifically for cigarette packaging (often referred to as ‘smoke-packers’), the latter tends to emphasize aspects tailored to the stringent requirements of the tobacco sector, such as enhanced sealing techniques and advanced anti-counterfeiting measures.

Conclusion

In essence, both transparent film three-dimensional packaging machines and ‘smoke-packers’ contribute significantly to the manufacturing landscape, providing high-quality, eco-friendly, and visually appealing packaging solutions across multiple sectors. Their adaptability and precision highlight the importance of these technologies in ensuring the safety, efficiency, and branding of products in their respective industries. Whether in the cosmetic world or the tobacco aisle, these machines serve as indispensable tools in the quest for excellence in product presentation and protection.

Transparent Film Three-Dimensional Packaging Machines: A Comprehensive Guide

Transparent film three-dimensional packaging machines, often referred to as 3D transparent film packers, vacuum packing machines, or even cigarette wrappers, are specialized machinery designed for the precise and efficient packaging of goods. Utilizing BOPP (Biaxially Oriented Polypropylene) film or PVC (Polyvinyl Chloride), these machines transform various products into compact, cubic, and sealed packages through an automated process.

Industry Applications

Ranging from cosmetics, pharmaceuticals, food, health care products, audio-video materials, stationery, daily-use items, to countless other industries, these packaging systems emulate the distinctive appearance of cigarette packaging, offering an array of functional and aesthetic advantages.

Key Features and Capabilities

A transparent film three-dimensional packaging machine encompasses a multitude of functionalities, including automatic feeding, wrapping, folding, side sealing, end sealing, bottom and top shaping, counting, among others. A notable feature is its capability to automatically apply tamper-evident pull-tabs. These pull-tabs can be customized with diverse colors and company logos, thereby enhancing their anti-counterfeiting function.

Eco-Friendly and Cost-Effective

The use of these machines is characterized by their environmental friendliness and energy conservation. They significantly reduce packaging material costs, while also ensuring neat and visually appealing packages. Full enclosure in packaging not only mitigates dust, moisture, and contamination, but also provides robust protection against counterfeits, making them a valuable addition to any production line.

Focus on Quality and Safety

For the tobacco industry, where the focus is on product quality and safety, specialized transparent film three-dimensional packaging machines, or ‘smoke-packers’, play a pivotal role. These machines are meticulously designed to prioritize packaging integrity and counterfeiting prevention, ensuring that each packaged item is secure and authentic.

Commonality and Specialization

While there is an overlap between the functions and applications of transparent film three-dimensional packaging machines and those utilized specifically for cigarette packaging (often referred to as ‘smoke-packers’), the latter tends to emphasize aspects tailored to the stringent requirements of the tobacco sector, such as enhanced sealing techniques and advanced anti-counterfeiting measures.

Conclusion

In essence, both transparent film three-dimensional packaging machines and ‘smoke-packers’ contribute significantly to the manufacturing landscape, providing high-quality, eco-friendly, and visually appealing packaging solutions across multiple sectors. Their adaptability and precision highlight the importance of these technologies in ensuring the safety, efficiency, and branding of products in their respective industries. Whether in the cosmetic world or the tobacco aisle, these machines serve as indispensable tools in the quest for excellence in product presentation and protection.

pinfupacking

pinfupacking

HelloPlease log in